For more aluminium foils technical documents, Download free in PDF form !!

aluminium foil

We are a professional manufacturer of aluminium foil,Aluminium Household Foil,Aluminium Container Foil,Aluminium Cable Foil,Aluminum sheet and Aluminum coil and have been exporting our products to overseas markets in the past 17 years.

We know you are searching for large quantity of aluminium foils in your market for long term. So how to reduce your cost and earn more profit will be a key problem of your side.

We would like to highlight our aluminum foil, Alumnium Cigarette Packing Foil, Aluminium Household Foil, Aluminium Container Foil, Aluminium Pharmaceutical Foil, Aluminium Cable Foil, Aluminium Beer Mark Foil, Aluminium Foil For Electronic Power Capacitor, Printed aluminium foil, Aluminium Hydrophilic Fin Stock Foil, Aluminium Hot Seal Foil and Aluminium foil for hair dressing with good quality and competitive price.

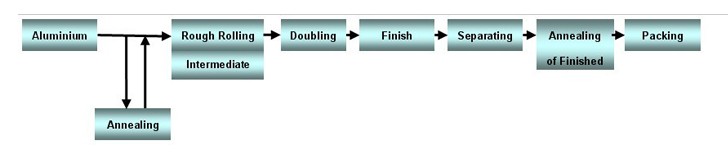

Production Process

The process of producing aluminium foils involves many steps, including refining, smelting, rolling and finishing before it becomes the common product that is used in households every day.

1.

2

Smell compounds, the first step in the production. Melting the aluminum oxide cell, the cell is carbon steel, and containing a liquid is heated conductor closed. Current generated by the crust, you will continue to fall off, dissolved, stirring inch aluminum will be created in the bottom of the aluminum mold. And input of aluminum melting pot, where you can add other elements of the alloy. There will be cast into the cold and then heated container. Scroll to the foil.

3

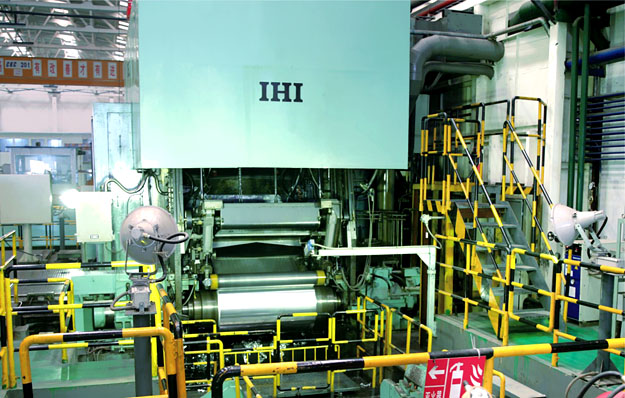

Extruded aluminium foil rolling mill and extrusion to the correct thickness. Occasionally, to maintain flexibility in the heating foil. The foil touches the surface of work roll surface, it creates a shiny completed, two will be rolling with the moving matte finish on both sides. At this point, trim the edges of foil, cut into small pieces of debris

4

To complete the coating has a wide range of material it foil. Resins and polymers can be used to protect or seal foil, or foil laminated paper or plastic film. Cutting, forming into the desired shape and foil printing or embossed patterns. Aluminum foil packaging for delive

Nunc fringilla congue congue. In blandit nisl sit amet diam consectetur eleifend. Nunc eget felis nisl, sodales facilisis erat. Vestibulum nec lacus sem, ac ullamcorper tortor. Nullam eleifend, arcu nec iaculis dapibus, urna metus dictum lectus, vel elementum enim felis vel odio.

Mechanical Propertie

Light yet strong, aluminium foil has unique deadfold characteristics which make it ideal for wrapping and re-wrapping many different products and product shapes, while minimising the need for sealants. Because it is very malleable it can be easily deformed without losing its barrier integrity, making it an ideal material for use in combination with other flexible substrates to create very thin laminates for a variety of markets and consequently, again, save resources.

Physical characteristics

Density |

2.7 g/cm³ |

Aluminium foil specific weight |

6.35 µm foil weighs 17.2 g/m2 |

Melting point |

660°C |

Electrical conductivity |

64.94% IACS (IACS: International Annealed Copper Standard) |

Electrical resistivity |

26.5 nΩm |

Thermal conductivity |

235 W/m K |

Thickness |

Foil is defined as measuring less than 0.2mm (<200 µm) |

History

Before aluminium foil

Foil made from a thin leaf of tin was commercially available before its aluminium counterpart. It was marketed commercially from the late nineteenth into the early twentieth century. The term "tin foil" survives in the English language as a term for the newer aluminium foil. Tin foil is less maleable than aluminium foil and tends to give a slight tin taste to food wrapped in it. Tin foil has been supplanted by aluminium and other materials for wrapping food.

The first audio recordings on phonograph cylinders were made on tin foil.

The first aluminium foil

Tin was first replaced by aluminium in 1910, when the first aluminium foil rolling plant, "Dr. Lauber, Neher & Cie." was opened in Emmishofen, Switzerland. The plant, owned by J.G. Neher & Sons, the aluminium manufacturers, started in 1886 in Schaffhausen, Switzerland , at the foot of the Rhine Falls - capturing the falls' energy to produce aluminium. Neher's sons together with Dr. Lauber discovered the endless rolling process and the use of aluminium foil as a protective barrier in December 1907.

Tel: +86-371-65621391

Fax: +86-371-65621393

Mobile: +86-13938245529

Mill Add: Xiaoguan Town, Gongyi, Henan,China

Office Add: 1103, First Int., No.14 Waihuan Road, CBD, Zhengzhou, China

Zip code: 450000